Your Cart is Empty

Free Shipping on orders over 99€ - EUROPE

Free Shipping on orders over 99€ - EUROPE

Free Shipping on orders over 99€ - EUROPE

In the past, when there were no machines to facilitate the olive oil production process, the olives were harvested manually, and the extraction process was carried out using traditional techniques.

Nowadays, the incorporation of new technologies to most oil mills has helped simplify the long process of producing olive oil, which has similarities and differences to the process of obtaining oil from ancient times.

The first step in the ancient production of olive oil revolved around young olive trees, which were cultivated with care and their olives were harvested with patience and respect for nature.

In ancient times, olive harvesting was done by hand, where the pickers were prepared with simple tools, and carefully selected the ripe olives, making sure to preserve the quality and integrity of the harvest.

Today, those young olive trees that the families of the time harvested stand as a symbol of history, with many of these trees being centuries old and even millenary. And although new technologies are currently used to facilitate the fruit harvesting process, the harvest of ancient olive trees is still done by hand to avoid damaging them.

The oil mill is the place where olives are turned into olive oil. Its process consists of 4 main phases that have varied over time:

For years, the grinding of olives was done with enormous millstones. These stones, driven by animal or hydraulic power, crushed the olives until they obtained a mass containing pulp, stone and skin.

Today, grinding is done with modern machines and mills equipped with advanced technology. This change has meant greater efficiency and control in the olive oil production process, guaranteeing higher quality in the final result.

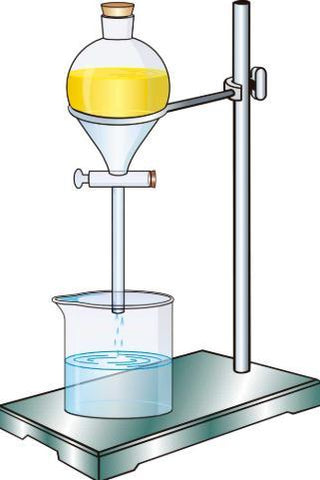

After grinding, it was time to press the resulting olive paste. In the old oil mills, pressing was carried out with beam and screw presses, which exerted pressure on the mass of olives to extract their juice. The liquid obtained was a mixture of water and oil, which was passed through a decantation process to separate both components.

Currently, this stage has experienced great technological advances. For this, modern presses are used, which can be hydraulic or mechanical. In addition, centrifugal extraction systems have been developed that separate the oil from the other parts of the mixture quickly and accurately.

In the past, the decantation process was based on the law of gravity. After grinding and pressing, the resulting liquid, which was a mixture of water and oil, was left to settle in large containers. Because oil is lighter than water, the oil rose to the surface, while the density of the water caused it to remain at the bottom. This process required a long period of time and a lot of patience until a clear and pure oil was obtained.

Centrifugation methods are currently used that accelerate the settling process thanks to centrifugal force to quickly separate the oil from water and sediments. Thanks to this, decantation is much faster and more efficient.

Once the olive oil was obtained, it was stored in clay, leather or wooden amphorae, which protected its flavor and properties. These containers traveled along trade routes in order to distribute the olive oil obtained to distant lands.

Today, stainless steel containers and vacuum packaging systems are used to preserve the freshness and flavor of the oil. These containers better protect the oil from light and air, factors that can affect its quality over time. In addition, new hermetic sealing techniques prevent oxidation and loss of organoleptic characteristics of the oil.

To understand the present it is essential to know the past of olive oil. Past generations have dedicated themselves to cultivating fields of olive trees that currently live as ancient olive trees and that give us the best fruits to make olive oil.

If you also want to try our most awarded ancient olive oil, click on the following link: